THEIC(1,3,5-Tris(2-hydroxyethyl)cyanuric acid)CAS 839-90-7

Chemical name: (1,3,5-Tris(2-hydroxyethyl)cyanuric acid)

Synonymous names:

THEIC

1,3,5-TRIS(2-HYDROXYETHYL)ISOCYANURIC ACID

CAS No.: 839-90-7

EINECS No.: 212-660-9

Molecular formula: C9H15N3O6

Molecular weight: 261.229 g/mol

Packaging:

25 KG/bag

500 KG/bag

Custom packaging available per client requirement

- Parameter

- Related products

- Inquiry

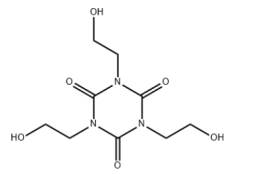

Structural formula:

1,3,5-Tris(2-hydroxyethyl)cyanuric acid Description:

Melting point |

135 °C-141 °C |

Density |

1.500g/cm3 |

|

Stability

|

Insoluble in oxidizing agents |

Hydroxyl value |

19.5KOHmg/G |

Storage conditions |

Dry; keep away from moisture |

PH |

6.5-7.5 |

What is THEIC (CAS 839-90-7)?

THEIC (1,3,5-Trihydroxyethyl Isocyanuric Acid,CAS NO.: 839-90-7) is a white crystalline powder with good thermal stability and high reactivity, used in powder coatings, flame retardant plastics, electrical insulating materials and UV light curing resins.

Compared with traditional cross-linking agent (such as Trimethylolpropane), THEIC can improve the temperature resistance (up to class H, 180°C), adhesion and long-term weathering resistance of the finished material while maintaining the stability of the system, which is especially suitable for export-grade industrial products or customized OEM formulation systems with strict quality requirements.

What is THEIC (CAS 839-90-7) used for?

1. Thermosetting resin crosslinker

THEIC (trihydroxyethyl isocyanuric acid) as a cross-linking agent can enhance the high temperature durability of polyester, epoxy and alkyd resins.

Such as in the unsaturated polyester resin to add 3% -7% or so of THEIC can improve the heat distortion temperature (HDT) about 1520 ° C.

2. Electrical insulating coatings

As an important additive for electrical paints and impregnating paints, THEIC can improve the dielectric strength and heat-resistant grade of the products, especially for Class H (180°C) motor paints.

Experimental data show that the breakdown voltage of insulating lacquers prepared in THEIC systems can be up to 2.5 times higher than that of unadded systems. They are widely used as coating materials for cables, motor windings and transformer windings.

3. Environmentally friendly coating formulations

In Low-VOC & Waterborne Coatings, THEIC is used as a non-volatile reactive additive that participates in the film-forming process of the resin without introducing additional solvents, and is suitable for automotive topcoats, industrial coatings, and wood finishes.

According to the test, volatile organic compounds (VOC) can be reduced to less than 40% of the original in the coating modified with THEIC.

4. Flame retardant additive synergists

Due to the high nitrogen content in the molecule, THEIC has a good synergistic flame retardant effect when compounded with phosphorus-based flame retardants (e.g. APP).

When used in plastics, cable sheaths or textile surface coatings, THEIC can form a dense carbonized layer, enhance smoke suppression and thermal stability, and meet the requirements of UL-94 V0 flame retardancy.

5. UV light curing system modifier

Add 1%~3% of THEIC in the UV curing system to help improve the flexibility and adhesion of the film layer, while taking into account the curing rate.

It is especially suitable for high-end electronic packaging, optical film layers and 3D printing coatings and other applications that require high structural strength and transparency.

Storage and Handling

Storage conditions: Store in a dry, sealed container in a well-ventilated area.

Moisture Sensitivity: Product is hygroscopic, avoid contact with humid environments.

Shelf life: 24 months under recommended conditions.

Safety: Non-toxic and non-flammable under normal conditions of use.

FAQ:

Q: What is the ideal amount of THEIC to use in an alkyd resin formulation?

A: Typically, 5-10% by weight of THEIC relative to the polyol content provides the best performance enhancement.

Q: Is THEIC compatible with isocyanate or melamine resins?

A: Yes, THEIC reacts effectively with isocyanates in polyurethane systems and has good synergy with melamine resins in heat cured coatings.

Q: Are there any REACH or RoHS compliance issues with THEIC?

A: No, THEIC is REACH registered and RoHS compliant. Documentation is available upon request.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

GA

GA

CY

CY

KA

KA

LA

LA

MN

MN

KK

KK

LB

LB